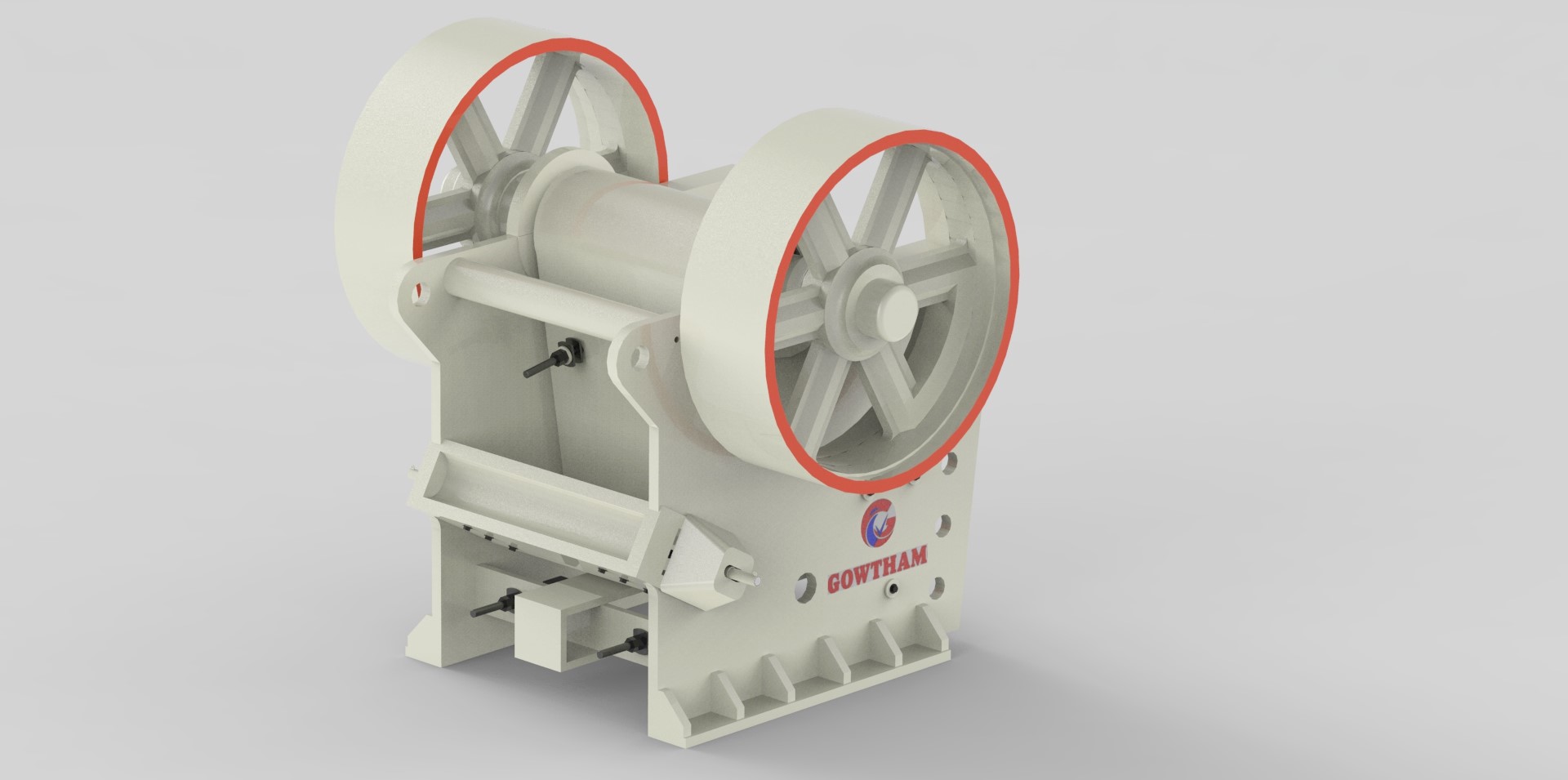

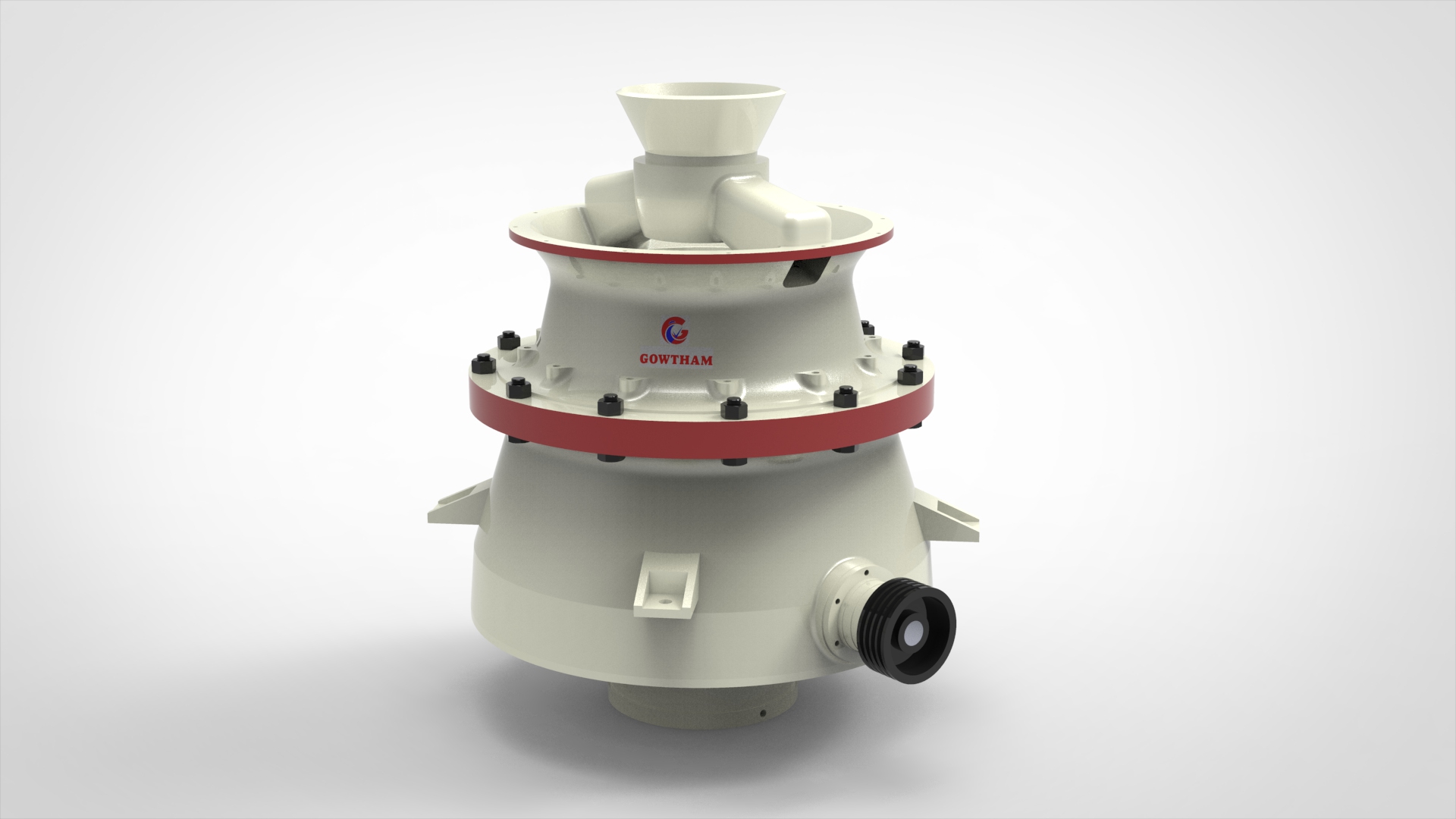

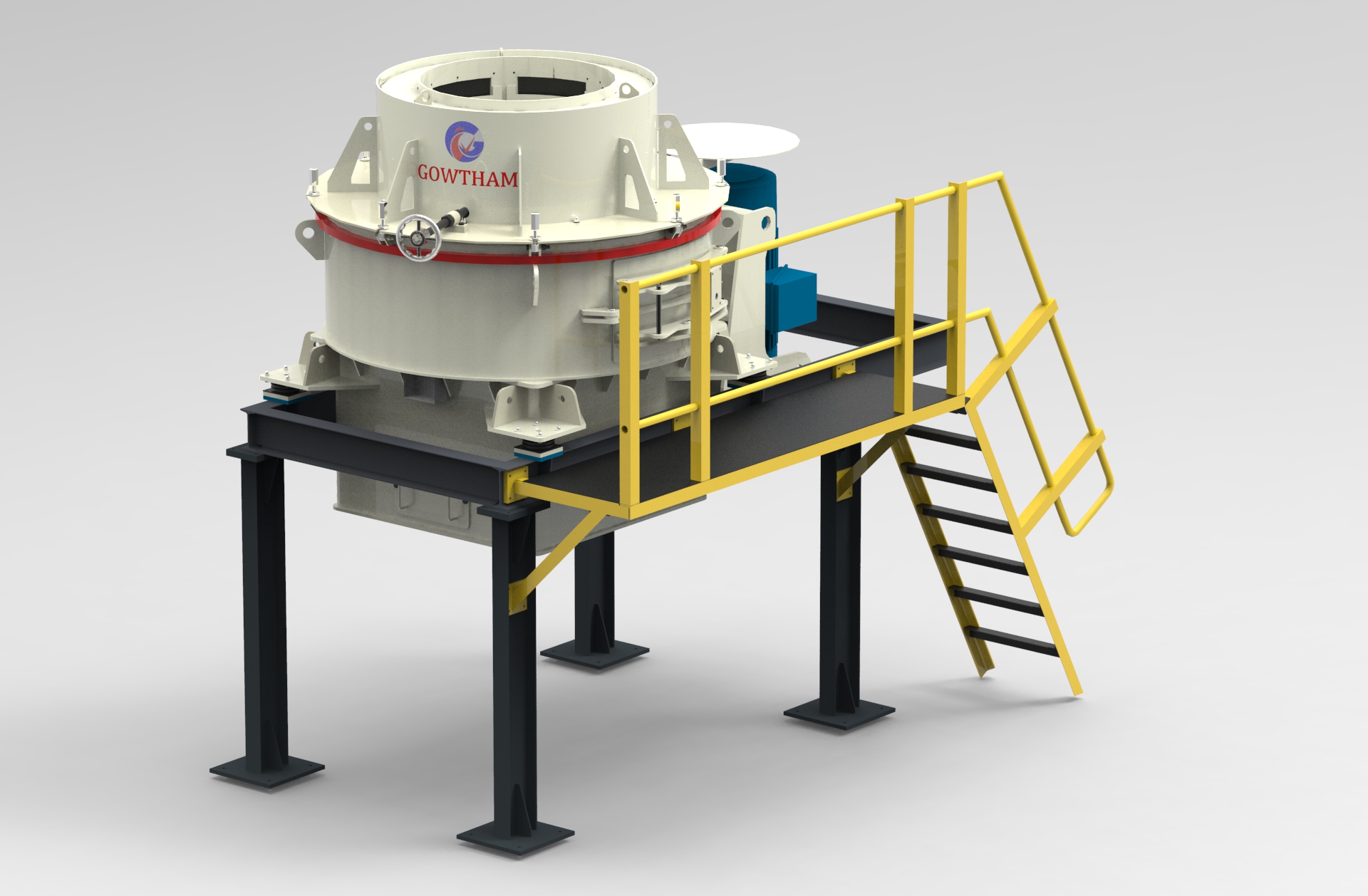

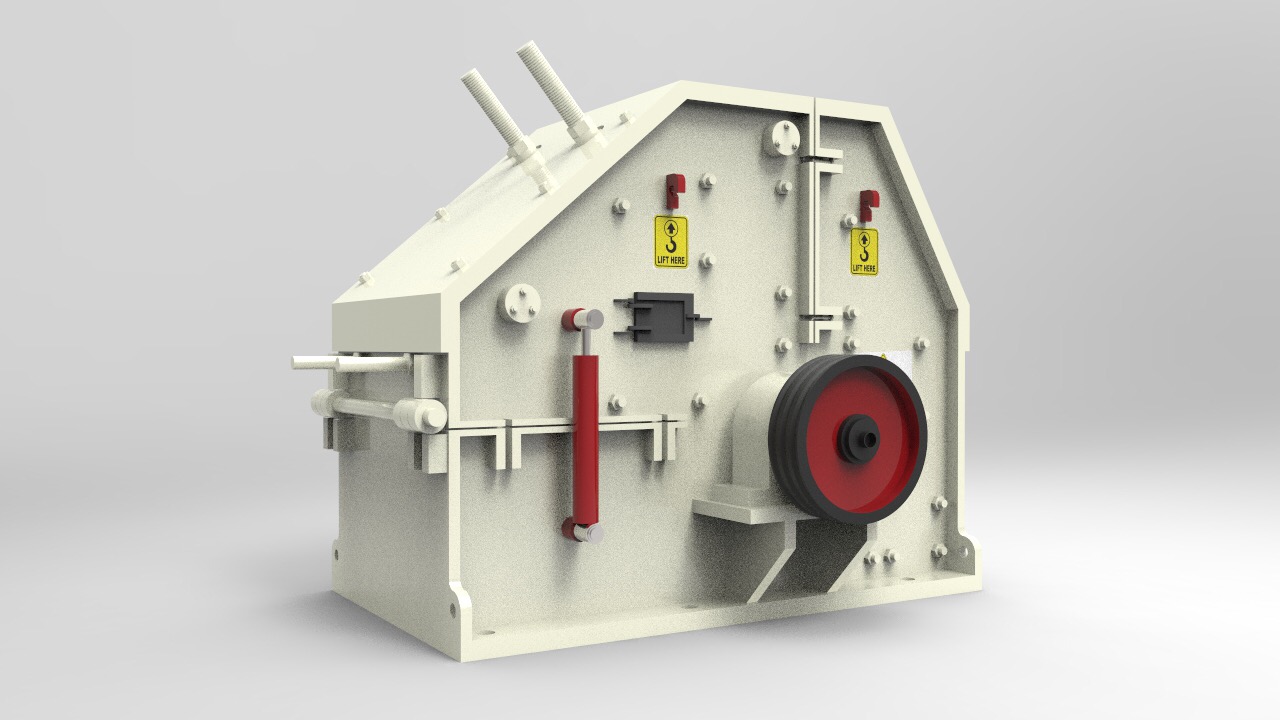

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical advantage through a material made of molecules that bond together more strongly, and resist deformation more, than those in the material being crushed do. Crushing devices hold material between two parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from (fracturing), or change alignment in relation to (deformation), each other. The earliest crushers were hand-held stones, where the weight of the stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these crushing devices.

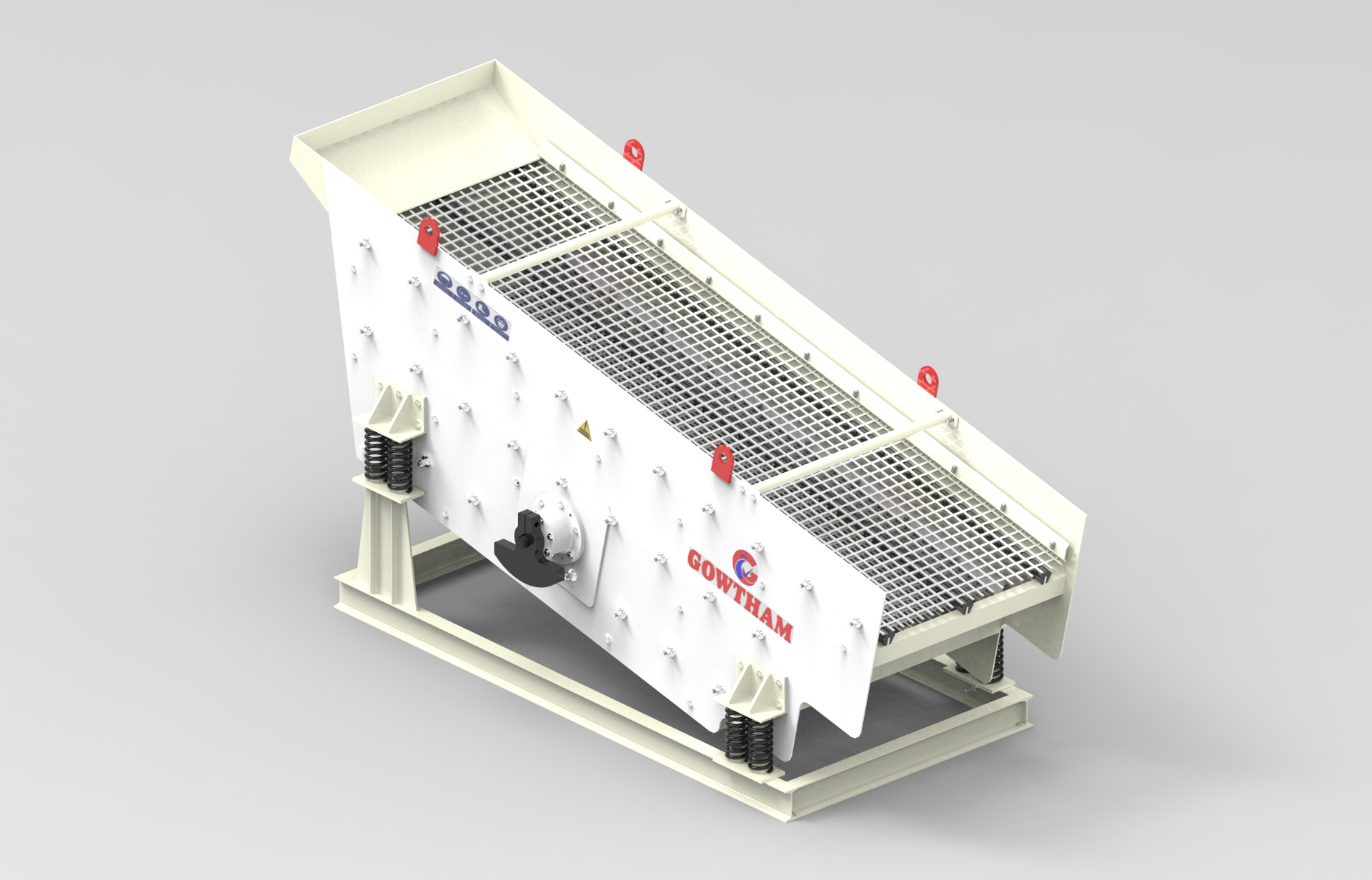

Screens are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material types, GOWTHAM screens provide screening efficiency that is high quality and dependable.

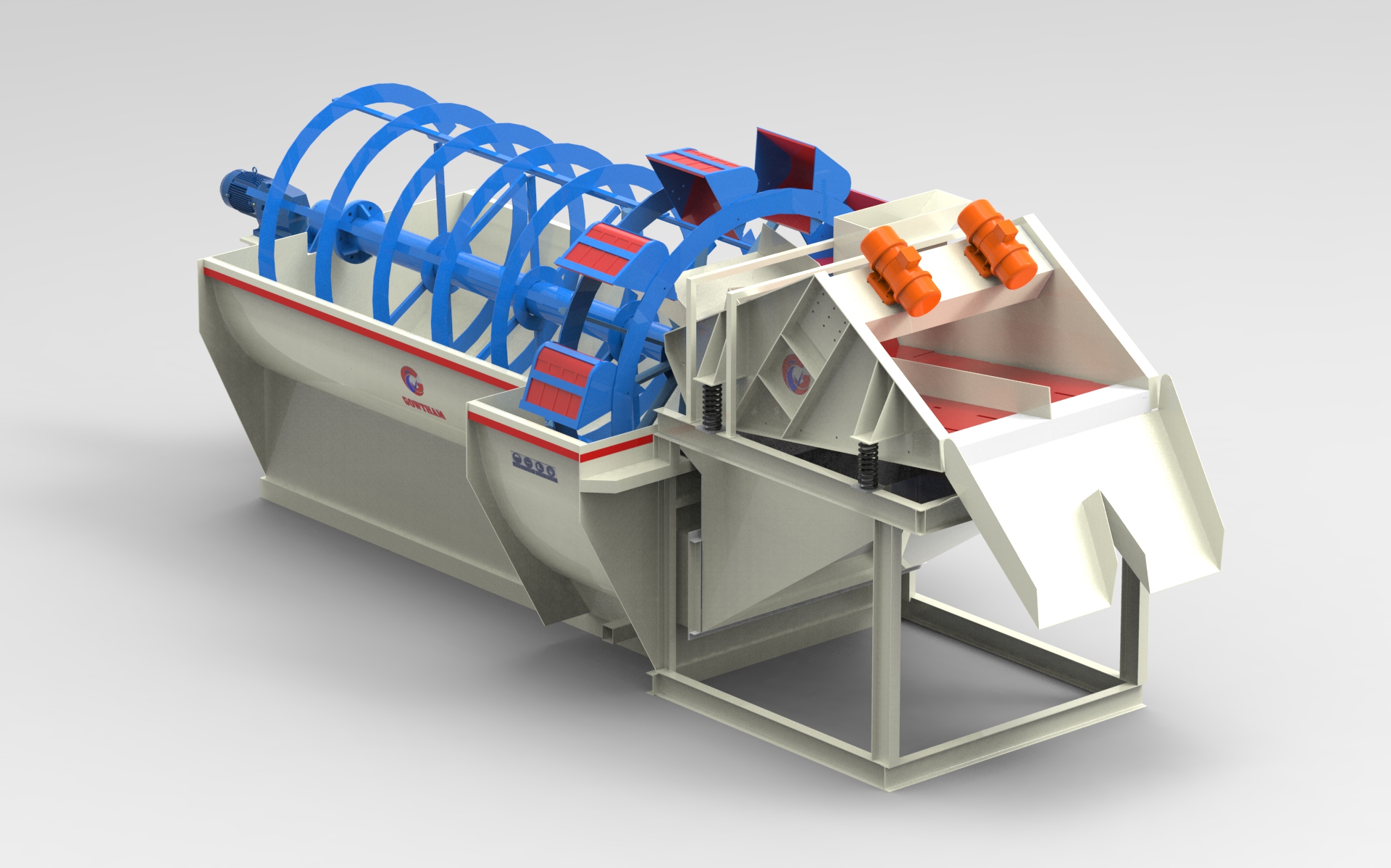

Sand Washer Machine is an ideal machine to wash and a separate silt and other impurities as well as dewatering sand after wash. It combines both the functions of washing and dewatering and is very effective.It consists of a slow rotating and gently elevating spiral screw in a tub with an inclined trough and its function is simple. Water is sprayed under pressure on to sand fines in the screen, and the sand slurry is gently let into the classifier tub full of water without causing any turbulence. The silt and other impurities get floated and discharged over weirs. The coarser particles i.e. sand settle at the bottom. The double start screw rotating at slow speed rakes up the settled sand particles and conveys up through the inclined trough. This is a continuous process and as the washed sand moves up the excess water in the sand mix is drained back to the tub and at the discharge point a relatively water free sand is obtained.

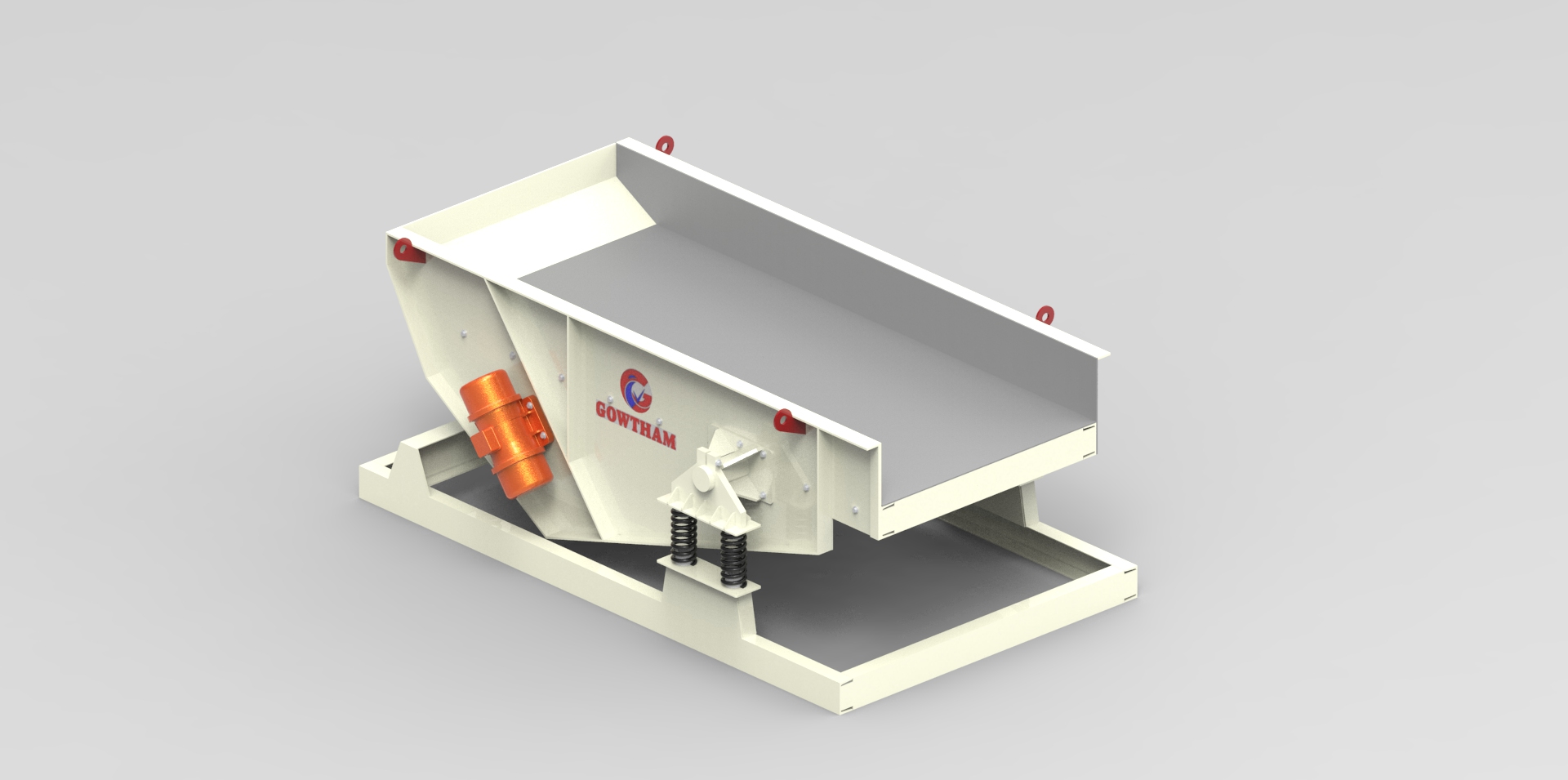

Feeder can send massive and granular materials from storage bin to feeding device evenly, regularly and continuously, at the same time, realize coarse sieving of materials, so vibratory feeder is widely used in crushing or screening production line in metallurgy, coal mine, mineral dressing, building materials, chemical, abrasive material and other industries.